Maximize Efficiency with Industrial Spring Isolators for Heavy Machinery

Industrial spring isolators are an essential component in maximizing the efficiency and performance of heavy machinery. These isolators play a critical role in reducing vibrations and noise, as well as protecting machinery from damage caused by excessive movement. By implementing industrial spring isolators, businesses can ensure that their heavy machinery operates smoothly and efficiently, ultimately leading to increased productivity and reduced maintenance costs. In this article, we will explore the benefits and applications of industrial spring isolators in various industrial settings.

Industrial spring isolators are essential components in heavy machinery that help maximize efficiency and performance. These isolators are designed to effectively reduce vibration and noise, while also providing stability and support for the machinery. By absorbing shocks and minimizing machine movement, spring isolators prevent damage to the equipment and surrounding structures. This ultimately leads to increased productivity, extended equipment lifespan, and a safer work environment for operators. With the right industrial spring isolators, heavy machinery can operate at optimal levels, leading to significant cost savings and improved overall efficiency.

Industrial spring isolators are critical for heavy machinery as they effectively minimize vibration, noise, and shock. These isolators offer stability and support to heavy machinery while reducing movement, preventing damage, and increasing productivity. By utilizing industrial spring isolators, heavy machinery can operate more efficiently, have a longer lifespan, and create a safer working environment for operators. This is achieved through the reduction of potential damage to the equipment and surrounding structures, resulting in cost savings and improved overall efficiency.

The Importance of Industrial Spring Isolators in Machinery

Industrial spring isolators are essential components in machinery as they serve to minimize the transmission of vibration and shock from the machinery to its surroundings. This is crucial for maintaining the stability and smooth operation of the machinery, as well as preventing damage to surrounding structures and equipment. Spring isolators also help to reduce noise and ensure the safety of workers by limiting the impact of vibrations on the overall work environment. Overall, the use of industrial spring isolators is a critical factor in the efficient and safe operation of industrial machinery.

How Industrial Spring Isolators Improve Workspaces and Equipment

Industrial spring isolators help improve workspaces and equipment by reducing vibrations and noise transmission. They are designed to absorb and isolate vibrations caused by machinery, engines, or other equipment. This helps create a quieter and more comfortable work environment for employees, as well as reduces the risk of damage to sensitive equipment. Additionally, industrial spring isolators can also help prolong the lifespan of machinery and improve overall efficiency by minimizing the effects of vibration on equipment performance. Overall, these isolators play a crucial role in creating a safer and more productive work environment.

The Advantages of Utilizing Industrial Spring Isolators in Manufacturing Plants

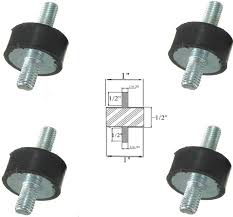

small vibration isolation mounts

Industrial spring isolators offer several advantages for manufacturing plants. First, they provide effective vibration isolation, minimizing the transfer of vibrations from machinery to the surrounding structure. This helps to reduce noise levels and prevent potential damage to other equipment or building structures. Additionally, spring isolators can help to improve the overall performance and lifespan of machinery by reducing the impact of vibrations. By isolating the equipment from external vibrations, the risk of wear and tear is minimized, resulting in cost savings on maintenance and repairs. Furthermore, utilizing spring isolators can enhance the safety of the workplace by reducing the risk of accidents and injuries caused by excessive vibrations. This can contribute to a healthier and more productive working environment for employees. Overall, the use of industrial spring isolators in manufacturing plants can lead to improved equipment performance, reduced maintenance costs, and a safer work environment.

Choosing the Right Industrial Spring Isolators for Your Facility

When choosing the right industrial spring isolators for your facility, it's important to consider the specific requirements and characteristics of your machinery and environment. Factors such as weight capacity, vibration frequency, and space limitations should be taken into account. Conducting a thorough assessment of your equipment and consulting with experienced professionals can help ensure that you select the most suitable spring isolators for your needs. Additionally, regular maintenance and inspections of the isolators are essential to ensure their continued effectiveness in reducing vibration and noise in your facility.

Maximizing Efficiency with Industrial Spring Isolators<

building vibration isolation/h2>

Industrial spring isolators are an effective solution for maximizing efficiency in a variety of industrial applications. These isolators are designed to reduce vibration and shock in machinery and equipment, which can lead to improved performance, longer equipment life, and safer working conditions. By using industrial spring isolators, companies can minimize the impact of vibrations on sensitive equipment, leading to reduced wear and tear, lower maintenance costs, and increased productivity. These isolators are also crucial for noise reduction, creating a quieter and more comfortable working environment. In addition, industrial spring isolators can help prevent damage to surrounding structures, machinery, and equipment by effectively isolating and dampening vibrations. This reduces the risk of equipment failure and costly repairs, ultimately leading to higher overall efficiency and cost savings for industrial operations. Overall, the use of industrial spring isolators can significantly improve operational efficiency and safety in industrial settings, making them a valuable investment for any company looking to maximize performance and minimize downtime.

The Role of Industrial Spring Isolators in Vibration Control

Industrial spring isolators play a critical role in controlling vibration in various industrial applications. These isolators are designed to absorb and dissipate vibration energy, thereby reducing the transmission of unwanted vibrations to adjacent structures or equipment. This helps in preventing equipment malfunction, structural damage, and occupational health hazards. Spring isolators are commonly used in a wide range of industrial equipment such as HVAC systems, pumps, generators, compressors, and other heavy machinery. They are effective in isolating both high and low-frequency vibrations, making them suitable for diverse industrial environments. By isolating the equipment from its surroundings, spring isolators not only reduce noise and discomfort but also enhance the overall efficiency and lifespan of the equipment. They also help in meeting regulatory requirements regarding vibration control and occupational safety. Overall, the role of industrial spring isolators in vibration control is crucial for ensuring smooth and safe operations in various industrial settings.

Understanding the Function of Industrial Spring Isolators in Heavy Machinery

Industrial spring isolators are essential components in heavy machinery as they serve to reduce vibration and noise caused by the operation of the equipment. These isolators function by absorbing and isolating the vibration and shock loads that are generated. This helps to protect not only the machinery itself, but also the surrounding structures and the people working in the vicinity. Additionally, industrial spring isolators also help to improve the overall performance and safety of the heavy machinery. By reducing the levels of vibration and noise, these isolators contribute to a smoother and more efficient operation of the equipment. They also help to minimize the risk of mechanical failures and malfunctions that can result from excessive vibration. Overall, understanding the function of industrial spring isolators in heavy machinery is crucial for ensuring the optimal performance, safety, and longevity of the equipment. These isolators play a critical role in mitigating the potentially damaging effects of vibration and shock loads, and their proper functioning is essential for the smooth and reliable operation of heavy machinery in various industrial settings.

The Impact of Industrial Spring Isolators on Equipment Maintenance Costs

Industrial spring isolators can have a significant impact on equipment maintenance costs. By effectively isolating machinery from external vibrations and shocks, spring isolators can reduce the wear and tear on equipment components, prolonging their service life and minimizing the need for repairs and replacements. This can lead to substantial cost savings for industrial operations, ultimately contributing to improved overall efficiency and productivity. Furthermore, by reducing the transmission of vibrations to surrounding structures, spring isolators can also help prevent damage to buildings and other nearby equipment, further minimizing maintenance costs and ensuring a safer working environment. Overall, the use of industrial spring isolators can have a substantial positive impact on equipment maintenance costs and should be considered as an important investment for industrial facilities.

In conclusion, industrial spring isolators are a crucial component for maximizing efficiency and reducing vibrations in heavy machinery. By effectively isolating and absorbing the impact of machinery movement, these isolators not only extend the lifespan of the equipment but also improve overall operational efficiency. Therefore, investing in high-quality industrial spring isolators is essential for ensuring smooth and stable operation of heavy machinery.

See also

https://www.acecontrols.com/us/products/vibration-isolation.html https://www.vibrationmounts.com/ https://www.rticontrols.com/vibration-isolation